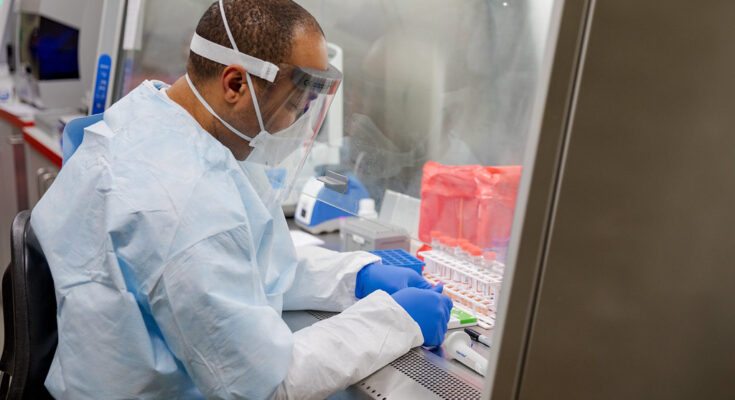

In the recent times it has been observed that there is an increase of contamination incidences among the COVID testing laboratories in the country. Because of these incidents an alarming delay in COVID 19 testing has been reported in these laboratories. So decontamination of these laboratories is an important factor in keeping these laboratories running in these tough conditions.

Contaminants in COVID RT PCR testing are amplicons or virus particles from outside the samples that are being tested and these contamination can affect the results of the tests. A contamination can occur in a lab via laboratory staff, cleaning staff, sample packages or through other supplies. At the same time, Amplicons can be released inside a laboratory from wastes of previous tests. There can be various other reasons as well behind these laboratory contamination incidents. In a contaminated environment, these amplicons and free virus particles can interfere ongoing PCR tests giving fault positive results. These false positives are mostly very light ones with Ct values just over 35 and can be visible in negative control channels as well.

Due to the present situation of the Covid testing laboratories both viral particles and amplicons can be accumulated in the laboratories due to following reasons.

- Overload of samples and limited time process securely.

- Higher number of positive samples giving chances of leaking to environment slightly.

- Mishandling and maintenance issues as of SOPs in the laboratory

- Personnel walking around (exhausted staff)

- Inadequate decontamination procedures in the laboratories

According to the recent observations, virus particles and amplicons are exposed in the laboratories frequently. It is very important to take precautions on regular basis.

Following solutions would be beneficial to minimize the contamination incidences.

- Decontaminate the lab use recommended commercial decontaminants every day after performing daily tasks. (Current solution Sodium hypochlorite is not enough as amplicons are cleaved around 35 – 40 base pair pieces. When using commercial decontaminants, they will be cleaved to base pair level).

- Use PCR plates with a proper sealer. When handling high numbers of samples, use of PCR plate always increase the efficiency and help avoid contaminations.

- Make sure the PCR tubes are well closed / sealed before PCR process commences

- Allocate separate staff for samples processing. They should not mix with others. Process leaders should be there to oversee each activity.

- Personnel should be trained and reminded regularly on SOPs even they are well experienced. Proper roaster should be in place making enough rest for the staff. And they should be kept free of viral infections.

- Waste disposal should be a regular task. Each PCR cycle generate billions of positive amplicons and they should be securely removed from the lab after each PCR test.

- Laboratories should follow daily maintenance tasks of GLP

- Weekly mandatory decontamination process should be carried out in these laboratories to prevent unnecessary lab closures.

In certain countries, they keep a back up laboratory for switching the testing process in case of a contamination. But a country without much resources, it is important to give higher priority for the prevention of contaminations.