In a special event held today a group of scientists from the University of Peradeniya introduced a new face mask with a 99% efficiency in removing and repelling harmful organisms including viruses. Research team from Faculty of Science, University of Peradeniya, headed by Prof. Gamini Rajapakse has developed this face mask with materials improved using nanotechnological techniques.

Along with Professor R.M.G. Rajapakse, Consultant Radiologist Dr. Chaminda Herath, together with Dr. R.B.S.D. Rajapakse, Mr. T.T.D.D. Senarathna, Mr. M.G.G.S. Thilakarathna and Mr. C. A. Thennakoon, as Nanotechnologists and Mr. Niroshan Samarasinghe as an Expert in Microscopy carried out this research project.

According to Prof. Rajapakse, this face mask comprises of three layers. The outermost layer is a superhydrophobic cotton layer that repels aerosol particles including droplets that can carry viral particles. The middle layer is also a modified cotton layer with Antiviral, Antibacterial and Mechanical properties and filter air using Electrostatic Filtration. The third and innermost layer is a hydrophilic layer that can absorb and evaporate liquid droplets. According to the researchers this face mask can be washed and reused for at-least without compromising the filter quality.

Speaking exclusively to the Sri Lankan Scientist, Prof. Rajapakse talked about the unique features of this new face mask,

“There are two modes of filtration: Mechanical filtration down to 300 nm particles and electrostatic binding of the negatively charged viral envelopes to the positively charged micro-particles used in blocking the pores of the cotton fabric. At the same time, all the materials used are environmentally friendly and bio-degradable unlike polypropylene used in some other standard masks. This new face mask is equipped with adjustable filtration at 300 nm to suit different cohorts of the population, excellent breathability and delayed flammability. As confirmed by the ITI test results this mask have shown a 99.85 to 99.99% bacterial filtration and 100% virus killing.”

“There is no detachment of particles even after 15 standard machine washing cycles as confirmed by XRF studies. Breathebility is 10 to 100 times better than the maximum allowable limit of 4 water mm per square centimeter as the pore blocking of the cotton is down to 300 nm to filter aerosol particles containing the virus if by chance they penetrate through the superhydrophobic upper layer allowing sufficient pore volumes for air molecules to go through. Flammability is 20 times better than the limit stipulated in the ISO test as cotton and inorganic materials take long time to catch fire when compared to polypropylene used in N-95 face masks.”

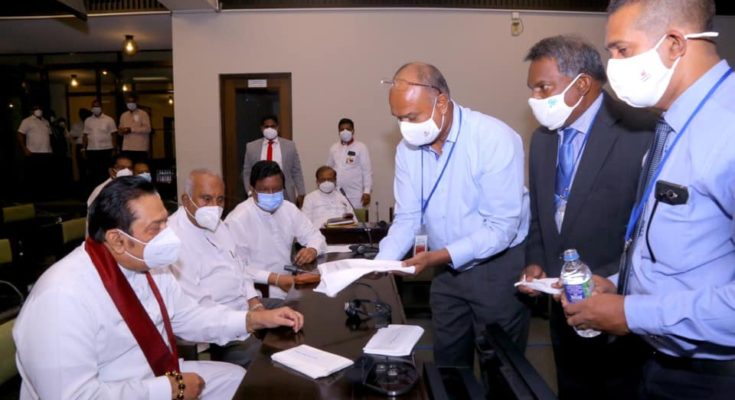

In today event Prof. Gamini Rajapakse and his team demonstrated the technologies used in developing this face mask to the Prime Minister of Sri Lanka, Hon. Mahinda Rajapaksa and a team of cabinet ministers. Prime Minster Mahinda Rajapaksa appreciating this fantastic and timely innovation assured the research team to give the maximum possible support from the government to take this to the mass production level and market the product locally and internationally.